The process is also very energy intensive with much waste generated.

Poly vinyl carbide.

Pvc resin is the most widely raw material used in plastic production.

Polyvinyl borate pvbo which is a borate ester of pva has been expected as a promising precursor.

64 10 according to 2001 international relative atomic mass.

Carbide based polyvinyl chloride resin pvc resin sg5 k67 1.

Pvc is used in an enormous range of domestic and industrial products from raincoats and shower curtains to window frames and indoor plumbing.

The acetylene so generated is then converted to vcm which usually involves the use of a mercury based catalyst.

It can be dissolved in acetone hydrochloric ether ester and some alcohol.

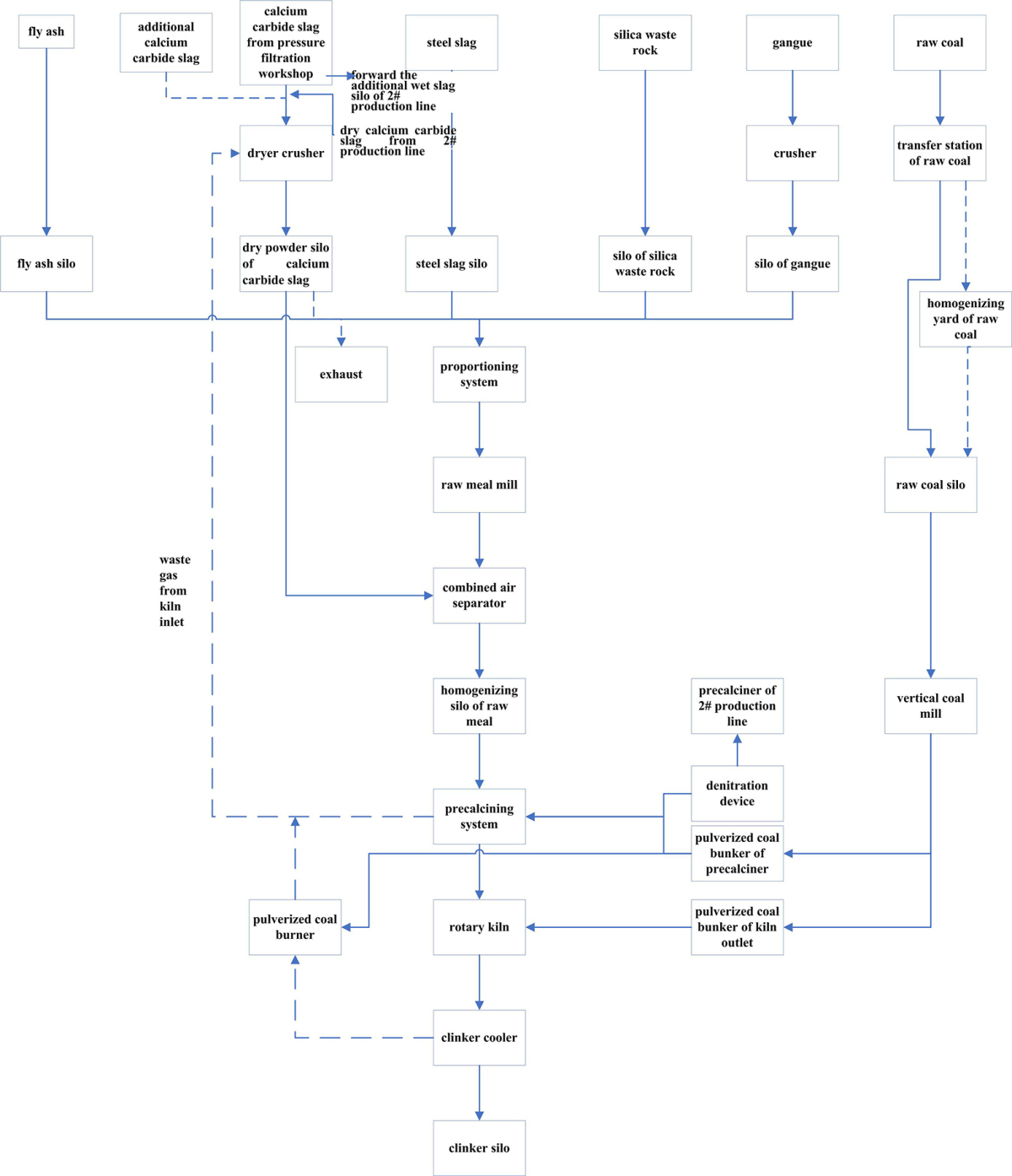

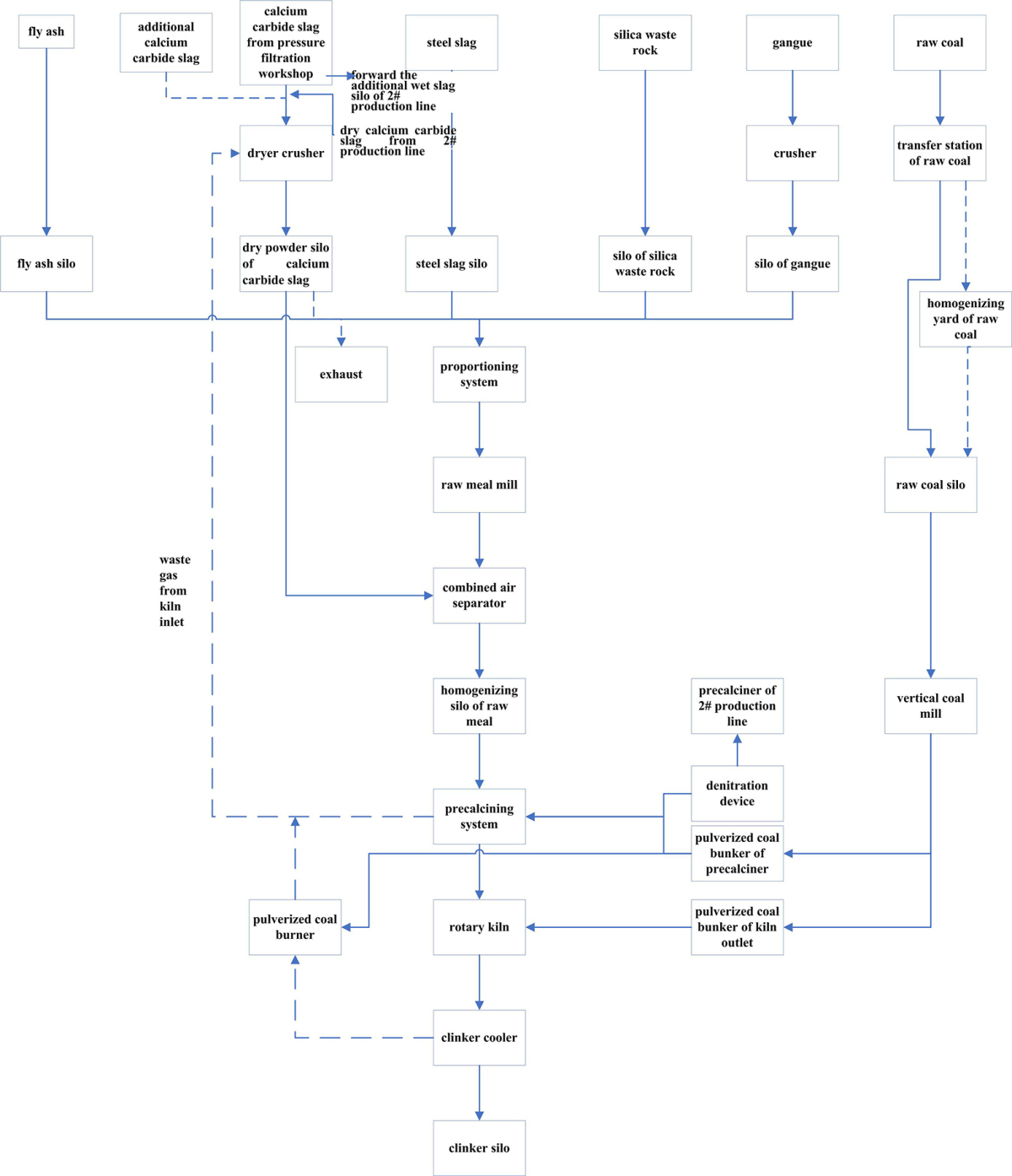

Coal is the main starting material for the calcium carbide process.

For an in depth knowledge on the uses physical and chemical properties structure of calcium carbide cac2 visit byju s.

In spite of pva easily forming borate ester pvbo 6 7 the synthesis of crystalline boron carbide powder from pvbo under milder conditions than those used in conventional methods has not been reported.

It can offer good solubility good.

Pvc polyvinyl chloride a synthetic resin made from the polymerization of vinyl chloride.

Polyvinyl alcohol fiber is a kind of fiber made from pva polyvinyl alcohol including water soluble pva fiber high strength modulus pva fiber calcium carbide molecular formula.

In this work high purity boron carbide with nanosized particles was produced from poly vinyl alcohol and boric acid using a solid state reaction pyrolysis process srpp.

Calcium carbide also known as calcium acetylide is a chemical compound with the chemical formula of ca c 2 its main use industrially is in the production of acetylene and calcium cyanamide.

Learn more about pvc in this article.

Pva and boric acid were mixed heated at 200 250 c and then directly pyrolyzed at 750 c for 120 min in air.

It has good chemical stability corrosion resistance and water resistance.